SIGNIFICANT POINTS

Job prospects for heating, air-conditioning, and refrigeration mechanics and installers are expected to be good, particularly for those with technical school or formal apprenticeship training.

The Air-Conditioning Excellence program, offered through North American Technician Excellence, is the standard for certification of experienced technicians.

NATURE OF THE WORK

What would those living in Chicago do without heating, those in Miami do without air-conditioning, or blood banks all over the country do without refrigeration? Heating and air-conditioning systems control the temperature, humidity, and the total air quality in residential, commercial, industrial, and other buildings. Refrigeration systems make it possible to store and transport food, medicine, and other perishable items. Heating, air-conditioning, and refrigeration mechanics and installers-also called technicians-install, maintain, and repair such systems. Because heating, ventilation, air-conditioning, and refrigeration systems often are referred to as HVACR systems, these workers also may be called HVACR technicians.

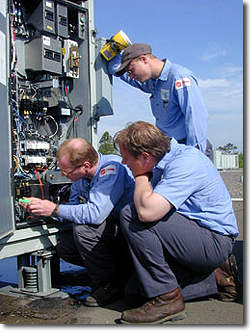

Heating, air-conditioning, and refrigeration systems consist of many mechanical, electrical, and electronic components, such as motors, compressors, pumps, fans, ducts, pipes, thermostats, and switches. In central heating systems, for example, a furnace heats air that is distributed throughout the building via a system of metal or fiberglass ducts. Technicians must be able to maintain, diagnose, and correct problems throughout the entire system. To do this, they adjust system controls to recommended settings and test the performance of the entire system using special tools and test equipment.

Heating, air-conditioning, and refrigeration systems consist of many mechanical, electrical, and electronic components, such as motors, compressors, pumps, fans, ducts, pipes, thermostats, and switches. In central heating systems, for example, a furnace heats air that is distributed throughout the building via a system of metal or fiberglass ducts. Technicians must be able to maintain, diagnose, and correct problems throughout the entire system. To do this, they adjust system controls to recommended settings and test the performance of the entire system using special tools and test equipment.

Technicians often specialize in either installation or maintenance and repair, although they are trained to do both. Some specialize in one type of equipment-for example, oil burners, solar panels, or commercial refrigerators. Technicians may work for large or small contracting companies or directly for a manufacturer or wholesaler. Those working for smaller operations tend to do both installation and servicing, and work with heating, cooling, and refrigeration equipment. Service contracts-which involve heating, air-conditioning, and refrigeration work for particular customers on a regular basis-are becoming more common. Service agreements help to reduce the seasonal fluctuations of this work.

Heating and air-conditioning mechanics install, service, and repair heating and air-conditioning systems in both residences and commercial establishments. Furnace installers, also called heating equipment technicians, follow blueprints or other specifications to install oil, gas, electric, solid-fuel, and multiple-fuel heating systems. Air-conditioning mechanics install and service central air-conditioning systems. After putting the equipment in place, they install fuel and water supply lines, air ducts and vents, pumps, and other components. They may connect electrical wiring and controls and check the unit for proper operation. To ensure the proper functioning of the system, furnace installers often use combustion test equipment, such as carbon dioxide and oxygen testers.

After a furnace has been installed, heating equipment technicians often perform routine maintenance and repair work to keep the system operating efficiently. During the fall and winter, for example, when the system is used most, they service and adjust burners and blowers. If the system is not operating properly, they check the thermostat, burner nozzles, controls, or other parts to diagnose and then correct the problem.

After a furnace has been installed, heating equipment technicians often perform routine maintenance and repair work to keep the system operating efficiently. During the fall and winter, for example, when the system is used most, they service and adjust burners and blowers. If the system is not operating properly, they check the thermostat, burner nozzles, controls, or other parts to diagnose and then correct the problem.

During the summer, when the heating system is not being used, heating equipment technicians do maintenance work, such as replacing filters, ducts, and other parts of the system that may accumulate dust and impurities during the operating season. During the winter, air-conditioning mechanics inspect the systems and do required maintenance, such as overhauling compressors.

Refrigeration mechanics install, service, and repair industrial and commercial refrigerating systems and a variety of refrigeration equipment. They follow blueprints, design specifications, and manufacturers' instructions to install motors, compressors, condensing units, evaporators, piping, and other components. They connect this equipment to the ductwork, refrigerant lines, and electrical power source. After making the connections, they charge the system with refrigerant, check it for proper operation, and program control systems.

When heating, air-conditioning, and refrigeration mechanics service equipment, they must use care to conserve, recover, and recycle chlorofluorocarbon (CFC) and hydrochlorofluorocarbon (HCFC) refrigerants used in air-conditioning and refrigeration systems. The release of CFCs and HCFCs contributes to the depletion of the stratospheric ozone layer, which protects plant and animal life from ultraviolet radiation. Technicians conserve the refrigerant by making sure that there are no leaks in the system; they recover it by venting the refrigerant into proper cylinders; and they recycle it for reuse with special filter-dryers.

Heating, air-conditioning, and refrigeration mechanics and installers are adept at using a variety of tools, including hammers, wrenches, metal snips, electric drills, pipe cutters and benders, measurement gauges, and acetylene torches, to work with refrigerant lines and air ducts. They use voltmeters, thermometers, pressure gauges, manometers, and other testing devices to check airflow, refrigerant pressure, electrical circuits, burners, and other components.

Other craftworkers sometimes install or repair cooling and heating systems. For example, on a large air-conditioning installation job, especially where workers are covered by union contracts, ductwork might be done by sheet metal workers and duct installers; electrical work by electricians; and installation of piping, condensers, and other components by pipelayers, plumbers, pipefitters, and steamfitters. Home appliance repairers usually service room air-conditioners and household refrigerators. (Additional information about each of these occupations appears elsewhere in the Handbook.)

WORKING CONDITIONS

Heating, air-conditioning, and refrigeration mechanics and installers work in homes, stores of all kinds, hospitals, office buildings, and factories-anywhere there is climate-control equipment. They may be assigned to specific jobsites at the beginning of each day, or if they are making service calls, they may be dispatched to jobs by radio, telephone, or pager. Increasingly, employers are using cell phones to coordinate technicians' schedules.

Technicians may work outside in cold or hot weather or in buildings that are uncomfortable because the air-conditioning or heating equipment is broken. In addition, technicians might have to work in awkward or cramped positions and sometimes are required to work in high places. Hazards include electrical shock, burns, muscle strains, and other injuries from handling heavy equipment. Appropriate safety equipment is necessary when handling refrigerants because contact can cause skin damage, frostbite, or blindness. Inhalation of refrigerants when working in confined spaces also is a possible hazard.

Technicians may work outside in cold or hot weather or in buildings that are uncomfortable because the air-conditioning or heating equipment is broken. In addition, technicians might have to work in awkward or cramped positions and sometimes are required to work in high places. Hazards include electrical shock, burns, muscle strains, and other injuries from handling heavy equipment. Appropriate safety equipment is necessary when handling refrigerants because contact can cause skin damage, frostbite, or blindness. Inhalation of refrigerants when working in confined spaces also is a possible hazard.

The majority of mechanics and installers work at least a 40-hour week. During peak seasons they often work overtime or irregular hours. Maintenance workers, including those who provide maintenance services under contract, often work evening or weekend shifts and are on call. Most employers try to provide a full workweek year-round by scheduling both installation and maintenance work, and many manufacturers and contractors now provide or even require service contracts. In most shops that service both heating and air-conditioning equipment, employment is stable throughout the year.

Heating, air-conditioning, and refrigeration mechanics and installers held about 249,000 jobs in 2002; almost half worked for cooling and heating contractors. The remainder was employed in a variety of industries throughout the country, reflecting a widespread dependence on climate-control systems. Some worked for fuel oil dealers, refrigeration and air-conditioning service and repair shops, schools, and stores that sell heating and air-conditioning systems. Local governments, the Federal Government, hospitals, office buildings, and other organizations that operate large air-conditioning, refrigeration, or heating systems employed others. About 15 percent of mechanics and installers were self-employed.

EMPLOYMENT

Heating, air-conditioning, and refrigeration mechanics and installers held about 249,000 jobs in 2002; almost half worked for cooling and heating contractors. The remainder was employed in a variety of industries throughout the country, reflecting a widespread dependence on climate-control systems. Some worked for fuel oil dealers, refrigeration and air-conditioning service and repair shops, schools, and stores that sell heating and air-conditioning systems. Local governments, the Federal Government, hospitals, office buildings, and other organizations that operate large air-conditioning, refrigeration, or heating systems employed others. About 15 percent of mechanics and installers were self-employed.

TRAINING, OTHER QUALIFICATIONS, AND ADVANCEMENT

Because of the increasing sophistication of heating, air-conditioning, and refrigeration systems, employers prefer to hire those with technical school or apprenticeship training. Many mechanics and installers, however, still learn the trade informally on the job.

Many secondary and postsecondary technical and trade schools, junior and community colleges, and the U.S. Armed Forces offer 6-month to 2-year programs in heating, air-conditioning, and refrigeration. Students study theory, design, and equipment construction, as well as electronics. They also learn the basics of installation, maintenance, and repair.

Many secondary and postsecondary technical and trade schools, junior and community colleges, and the U.S. Armed Forces offer 6-month to 2-year programs in heating, air-conditioning, and refrigeration. Students study theory, design, and equipment construction, as well as electronics. They also learn the basics of installation, maintenance, and repair.

Apprenticeship programs frequently are run by joint committees representing local chapters of the Air-Conditioning Contractors of America, the Mechanical Contractors Association of America, the National Association of Plumbing-Heating-Cooling Contractors, and locals of the Sheet Metal Workers' International Association or the United Association of Journeymen and Apprentices of the Plumbing and Pipefitting Industry of the United States and Canada. Other apprenticeship programs are sponsored by local chapters of the Associated Builders and Contractors and the National Association of Home Builders. Formal apprenticeship programs normally last 3 to 5 years and combine on-the-job training with classroom instruction. Classes include subjects such as the use and care of tools, safety practices, blueprint reading, and the theory and design of heating, ventilation, air-conditioning, and refrigeration systems. Applicants for these programs must have a high school diploma or equivalent. Math and reading skills are essential.

Those who acquire their skills on the job usually begin by assisting experienced technicians. They may begin by performing simple tasks such as carrying materials, insulating refrigerant lines, or cleaning furnaces. In time, they move on to more difficult tasks, such as cutting and soldering pipes and sheet metal and checking electrical and electronic circuits.

Courses in shop math, mechanical drawing, applied physics and chemistry, electronics, blueprint reading, and computer applications provide a good background for those interested in entering this occupation. Some knowledge of plumbing or electrical work also is helpful. A basic understanding of electronics is becoming more important because of the increasing use of this technology in equipment controls. Because technicians frequently deal directly with the public, they should be courteous and tactful, especially when dealing with an aggravated customer. They also should be in good physical condition because they sometimes have to lift and move heavy equipment. All technicians who purchase or work with refrigerants must be certified in their proper handling. To become certified to purchase and handle refrigerants, technicians must pass a written examination specific to the type of work in which they specialize. The three possible areas of certification are: Type I-servicing small appliances, Type II-high-pressure refrigerants, and Type III-low-pressure refrigerants. Exams are administered by organizations approved by the U.S. Environmental Protection Agency, such as trade schools, unions, contractor associations, or building groups.

Several organizations have begun to offer basic self-study, classroom, and Internet courses for individuals with limited experience. In addition to understanding how systems work, technicians must be knowledgeable about refrigerant products and the legislation and regulations that govern their use. The Air-Conditioning Excellence program, which is offered through North American Technician Excellence (NATE), generally has been adopted as the standard for certification of experienced technicians.

Advancement usually takes the form of higher wages. Some technicians, however, may advance to positions as supervisor or service manager. Others may move into areas such as sales and marketing. Still others may become building superintendents, cost estimators, or, with the necessary certification, teachers. Those with sufficient money and managerial skill can open their own contracting business.

JOB OUTLOOK

Job prospects for heating, air-conditioning, and refrigeration mechanics and installers are expected to be good, particularly for those with technical school or formal apprenticeship training. Employment of heating, air-conditioning, and refrigeration mechanics and installers is expected to grow faster than the average for all occupations through the year 2012. As the population and economy grow, so does the demand for new residential, commercial, and industrial climate-control systems. Technicians who specialize in installation work may experience periods of unemployment when the level of new construction activity declines, but maintenance and repair work usually remains relatively stable. People and businesses depend on their climate-control systems and must keep them in good working order, regardless of economic conditions.

Renewed concern for energy conservation should continue to prompt the development of new energy-saving heating and air-conditioning systems. An emphasis on better energy management should lead to the replacement of older systems and the installation of newer, more efficient systems in existing homes and buildings. Also, demand for maintenance and service work should increase as businesses and homeowners strive to keep systems operating at peak efficiency. Regulations prohibiting the discharge of CFC and HCFC refrigerants took effect in 1993, and regulations banning CFC production became effective in 2000. Consequently, these regulations should continue to result in demand for technicians to replace many existing systems, or modify them to use new environmentally safe refrigerants. In addition, the continuing focus on improving indoor air quality should contribute to the creation of more jobs for heating, air-conditioning, and refrigeration technicians. Also, growth of business establishments that use refrigerated equipment-such as supermarkets and convenience stores-will contribute to a growing need for technicians. In addition to job openings created by employment growth, thousands of openings will result from the need to replace workers who transfer to other occupations or leave the labor force.

EARNINGS

Median hourly earnings of heating, air-conditioning, and refrigeration mechanics and installers were $16.78 in 2002. The middle 50 percent earned between $12.95 and $21.37 an hour. The lowest 10 percent earned less than $10.34, and the top 10 percent earned more than $26.20. Median hourly earnings in the industries employing the largest numbers of heating, air-conditioning, and refrigeration mechanics and installers in 2002 were as follows:

Hardware, and plumbing and heating equipment

and supplies merchant wholesalers | $18.78 |

Commercial and industrial machinery and equipment

(except automotive and electronic) repair and maintenance | $17.16 |

| Direct selling establishments | $17.14 |

| Elementary and secondary schools | $16.80 |

| Building equipment contractors | $16.03 |

Apprentices usually begin at about 50 percent of the wage rate paid to experienced workers. As they gain experience and improve their skills, they receive periodic increases until they reach the wage rate of experienced workers. Heating, air-conditioning, and refrigeration mechanics and installers enjoy a variety of employer-sponsored benefits. In addition to typical benefits such as health insurance and pension plans, some employers pay for work-related training and provide uniforms, company vans, and tools. About 20 percent of heating, air-conditioning, and refrigeration mechanics and installers are members of a union. The unions to which the greatest numbers of mechanics and installers belong are the Sheet Metal Workers' International Association and the United Association of Journeymen and Apprentices of the Plumbing and Pipefitting Industry of the United States and Canada.

RELATED OCCUPATIONS

Heating, air-conditioning, and refrigeration mechanics and installers work with sheet metal and piping, and repair machinery, such as electrical motors, compressors, and burners. Other workers who have similar skills include boilermakers; home appliance repairers; electricians; sheet metal workers; and pipelayers, plumbers, pipefitters, and steamfitters.

SOURCES OF ADDITIONAL INFORMATION

For more information about opportunities for training, certification, and employment in this trade, contact local vocational and technical schools; local heating, air-conditioning, and refrigeration contractors; a local of the unions or organizations previously mentioned; a local joint union-management apprenticeship committee; or the nearest office of the State employment service or apprenticeship agency.

For information on career opportunities, training, and technician certification, contact:

Air-Conditioning Contractors of America (ACCA), 2800 Shirlington Rd., Suite 300, Arlington, VA 22206.

Internet: http://www.acca.org

Refrigeration Service Engineers Society (RSES), 1666 Rand Rd., Des Plaines, IL 60016-3552.

Internet: http://www.rses.org

Plumbing-Heating-Cooling Contractors (PHCC), 180 S. Washington St., P.O. Box 6808, Falls Church, VA 22046.

Internet: http://www.phccweb.org

Sheet Metal and Air-Conditioning Contractors' National Association, 4201 Lafayette Center Dr., Chantilly, VA 20151-1209.

Internet: http://www.smacna.org

For information on technician testing and certification, contact:

North American Technician Excellence (NATE), 4100 North Fairfax Dr., Suite 210, Arlington, VA 22203.

Internet: http://www.natex.org

For information on career opportunities and training, contact:

Associated Builders and Contractors, Workforce Development Department, 4250 North Fairfax Dr., 9th Floor, Arlington, VA 22203.

Home Builders Institute, 1201 15th St. NW., 6th Floor, Washington, DC 20005-2800.

Internet: http://www.hbi.org

Mechanical Contractors Association of America, 1385 Piccard Dr., Rockville, MD 20850-4329.

Internet: http://www.mcaa.org

Air-Conditioning and Refrigeration Institute, 4100 North Fairfax Dr., Suite 200, Arlington, VA 22203.

Internet: http://www.ari.org

There are more than 500 occupations registered by the U.S. Department of Labor's National Apprenticeship System.

For more information on the Labor Department's registered apprenticeship system and links to State apprenticeship programs, check their Web site: http://www.doleta.gov

|